SF Froth pump

| ● Capacity: | Up to 650 m3/h |

|---|---|

| ● Head: | Up to 30 m |

| ● Discharge Size: | 2 – 8 inches |

| ● Handing solids to: | 79mm |

Key word:

Slurry Pumps,Gravel Sand Pumps

Category:

SF Pump

Products detail

detail

The FROTH PUMP SF series is a new generation of products. Now, it is widely used in metallurgical, mining, coal, chemical and other industrial sectors. It is mostly used to handle abrasive or corrosive frothy slurries, mainly in flotation.

It can still work normally under the case of material shortages, and features a wide choice for various flotation processes. It is an ideal product for conveying foam pulp.

Hard metal lined vertical froth pumps SF series have been designed to increase the pumpability of frothy slurry. The principle of operation is similar to that of hydrocyclone separation.

Standard pumps are supplied with parts in wear resistant high chrome iron alloy, with a nominal hardness of 58-65HRC.

The SF froth pump is ideal for all applications involving handling of air entrained slurries, such as flotation froth in base metal concentrators, phosphate and apatite washing plants and calcium carbonate upgrading plants. The pump can also be used as a mixing and distribution unit, where dry powder has to be mixed with water.

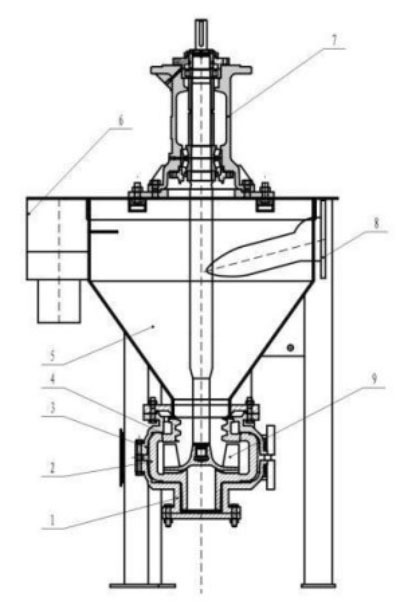

AF series pumps structure is simple, the most commonly used, easy to install and use. The structural characteristics are as follows:

1. This type of pump used in SP, SPR, PNL bearing assembly, and the bearing body is equipped with motor base or electric frame, that is, direct drive or indirect drive can be adopted, easy replacement of pulley, used to change the speed of pump, to meet the change of working conditions.

2. The hopper is made of steel structure or stainless steel, steel liner rubber etc., with tangential feed port and overflow box, the overflow box can conveniently put the excess materials sent back to the feed pool again, the tangential inlet port could enable the material to enter the pump quickly and eliminate some foam.

3. The pump head structure is a split casing, depending on the medium of transport, the wetted spares could choose from: metal, rubber, or other non-metallic materials.

| 1.Cover plate |

| 2.Volute liner | |

| 3.Frame plate | |

| 4.Spiral front liner | |

| 5.Feeding box | |

| 6.Overflow | |

| 7.Bearing assembly | |

| 8.Feeding inlet | |

| 9.Impeller | |

| Note: this is the basic drawing of structure. There would be some differences up to varied discharge size. |

| Pump Model | Allowable Max. Power (kw) | Material | Clear Water Performance | Diameter | ||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | Suction (mm) | Discharge (mm) | |||

| Impeller | m3/h | |||||||

| SF/50QV | 15 | Metal (A05) | 7.6-42.8 | 6-29.5 | 800-1800 | 45 | 100 | 50 |

| SF/75QV | 18.5 | 23-77.4 | 5-28 | 700-1500 | 55 | 150 | 75 | |

| SF/100RV | 37 | 33-187.2 | 5-28 | 500-1050 | 55 | 150 | 100 | |

| SF/150SV | 75 | 80-393 | 5-25 | 250-680 | 55 | 200 | 150 | |

| SF/200SV | 110 | 126-575 | 5.5-25.5 | 350-650 | 55 | 250 | 200 | |

Factory

FAQ

★ How can we guarantee quality?

Tests starting from material, casting, to machining, assembly,etc. are all done by our experienced & professional operators and advanced equipments which can ensure the top quality of every component to the whole machine.

★ What products do we have?

Horizontal slurry pumps (SH, SHH, SL,SM), Vertical slurry pump(SV, SVR), Gravel/Sand pump, Dredger pump, ZGB Series Slurry pump, ZJ Series Slurrypump, SPP& SHPP, Froth pump and spare parts or OEM.

★ Are you the manufacturer or trading company?

We are professional manufacturer for slurry pumps and spare parts for more than 20 years in the industry located in Shijiazhuang City.

★ What is your delivery time?

Fast delivery time. We have lots of inventory in our factory for the common pump parts.

★ What is your MOQ?

No MOQ requirement.

★ Can we visit your company?

We always welcome customers from different countries coming to our factory for visits and further communications.

IF the above questions don’t answer yours, send us messages online, or send email to us directly.

Prev

None

Next

ONLINE MESSAGE

Related products

| ● Discharge Size: | 1" to 6" |

|---|---|

| ● Capacity: | 16.2-1008 m³/h |

| ● Head to: | 12-118m |

| ● Handing solids to: | 0-70mm |

| ● Capacity: | Up to 1,180 m3/h or 5,200 US gpm |

|---|---|

| ● Head: | Up to 55 m or 180 feet |

| ● Working Pressure: | 750 kPa or 110 psi |

| ● Discharge Size: | 40 – 250 mm or 1.5 – 10 inches |

| ● Capacity: | Up to 1,180 m3/h or 5,200 US gpm |

|---|---|

| ● Head: | Up to 55 m or 180 feet |

| ● Working Pressure: | 750 kPa or 110 psi |

| ● Discharge Size: | 40 – 250 mm or 1.5 – 10 inches |

| ● Discharge Size: | 1" to 6" |

|---|---|

| ● Capacity: | 16.2-1008 m³/h |

| ● Head to: | 12-118m |

| ● Handing solids to: | 0-70mm |